Chemical Metering Pumps

FPZ offers pumps and systems for the dosing of chemcials, acids and other liquids. When precise metering of liquids is required, FPZ has a solution.

Explore our Download Center to access a wide range of resources tailored to enhance your experience.

Rapida 2.0 is a quick and easy way to meter the desired amount of fluid. The graphic display can show flow, percentage of speed or percentage of frequency. Manual or remote options are available.

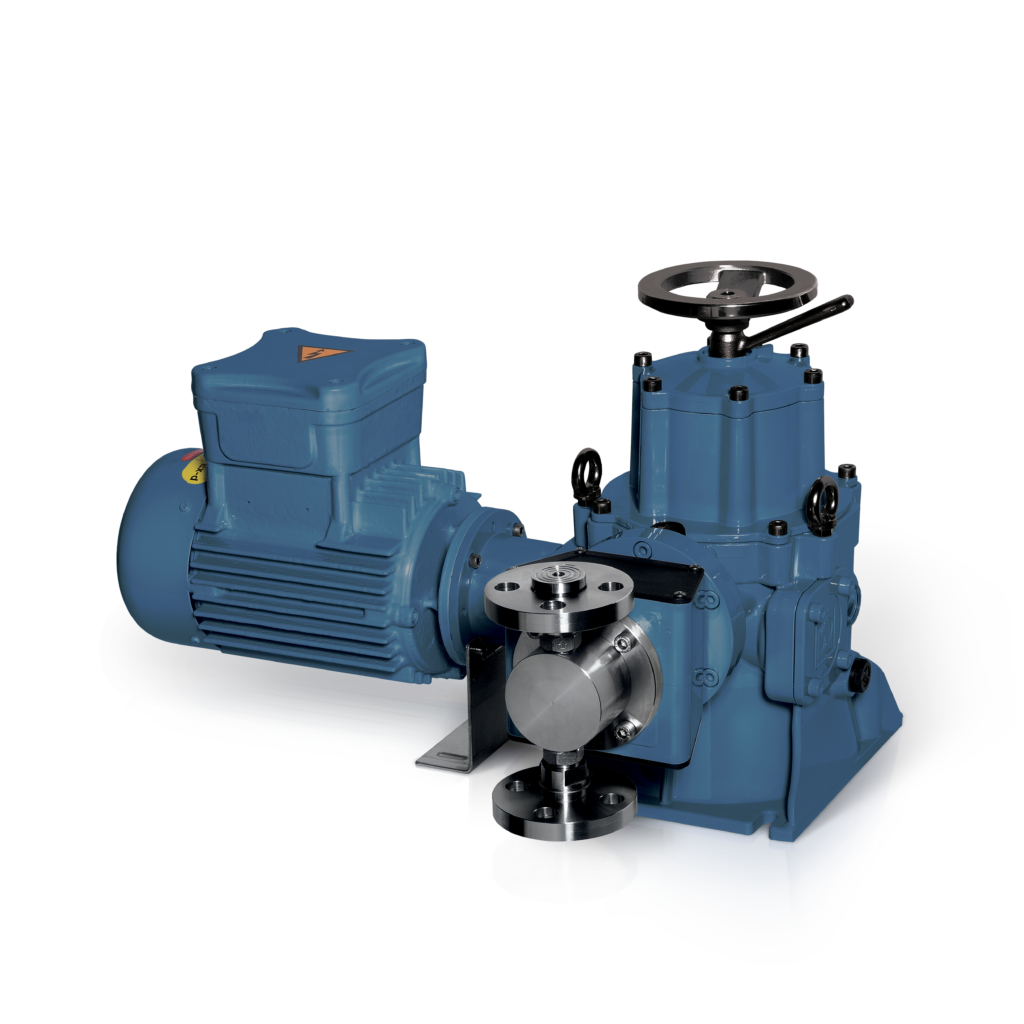

FM , D and DV series mechanical diaphragm pumps are easy to install and maintain. Equipped with an endless screw worm type gearbox, stroke adjustment can be made while the pump is in operation or at rest. A wide range of wetted materials are available to handle practically any fluid.

SD and AP SD sandwhich Hydaulic Diaphragm pumps are capable of pressures to 580 psi and flows to 146 gph. These pumps have a built-in safety valve installed in the hydraulic circuit in order to protect the daphragm against over pressure. Stroke adjustment can be made while the pump is in operation or at rest.

FPZ’s A and AP series spring return plunger pumps are capable of pressures over 3,300 psi and flows to 385 gph. Stroke adjustment can be made while the pumps are in operation or at rest.

FPZ models B, BR, and AP B and AP BR spring retrun hydraulic diaphram pumps feature flows to 282 gph and pressures to 870 psi. BR versions are equipped with a built-in safety valve installed int he hydraulic circuit to protect the diaphragm from over pressure.

The AI series plunger dosing pumps meet both mechanical and performance API 675 standards and offer options for Explosion Proof or Division II electric motors, ideal for hazardous environments. Their internal worm gear mechanism, fully lubricated in an oil bath, seamlessly couples with other units to create multi-head setups, regardless of size or stroke number. Stroke adjustment, whether manual or automatic, is possible even during operation, thanks to automatic actuators driven by 4-20 mA signals, various BUS systems, or pneumatic mechanisms, ensuring accuracy within ±1% across 10-100% of the rated capacity. These pumps are reliable, easy to maintain, and can include optional flushing or leakage recovery systems. They support a wide range of wetted materials, including S.S.316L, PVC, PP, PVDF, PTFE, with additional options available upon request.

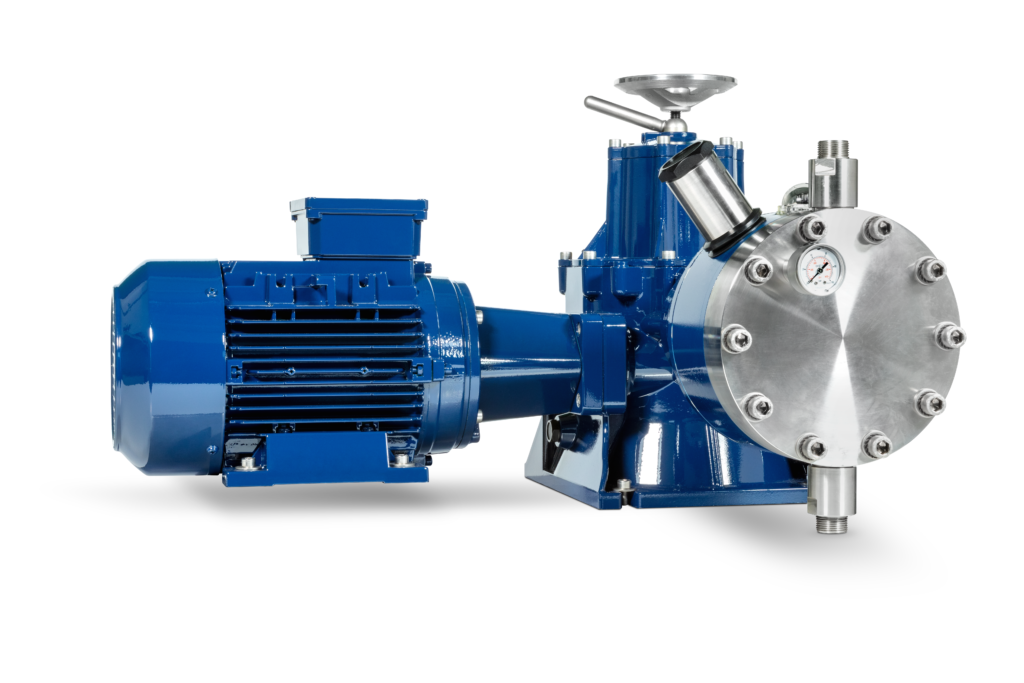

SDI Sandwich Hydraulic Diaphragm Dosing Pumps meet both mechanical and performance API 675 standards. They’re designed for hazardous environments, offering options for Explosion Proof or Division II electric motors. The internal worm gear mechanism is fully lubricated and can integrate seamlessly with other units for multi-head setups, regardless of size or stroke number. Stroke adjustment options include manual or automatic control via a 4-20 mA actuator, various BUS systems, or pneumatic mechanisms, ensuring accuracy within ±1% across the rated capacity range. With a built-in safety valve to prevent overpressure and a reliable rupture detection system, these pumps feature a unique sandwich diaphragm design. They’re compatible with wetted materials such as S.S.316L, PVC, PP, PVDF, and PTFE, with customization available upon request.

Explore our Download Center to access a wide range of resources tailored to enhance your experience.